Our Why

Ico Traders is only a small company, but we care deeply about this issue & we know that lots of small companies can add up to big numbers of people making changes!

We’ve seen the negative effect that the fast fashion industry has on the environment, it was one of the reasons for making a career change from the clothing industry. At Ico Traders we design furniture made from steel, a sustainable resource and a recyclable material. We audit our business yearly and positively contribute 120% carbon credits to offset our footprint. This year we audited the suppliers we work with here in New Zealand and we have begun the process to audit our offshore suppliers as well. N/B – Our offshore factories are already audited for Health and Safety of staff and environmental impacts yearly, however, we want to expand on this to understand not only our factories, but our factories suppliers as well.

We are not perfect, but we are willing to invest in learning & contributing to change. We recognise we all need to play a part in reaching the Paris agreement goal of Net Zero NZ 2050.

This is a global problem & requires a global solution. We need every person and every business big or small, to go the extra mile & help reduce our negative impact on the world.

Our Operational Impact

- Steel is one of the most recyclable materials on earth. After years of use our furniture can be stripped back and re-powder coated to look brand new.

- We design items that are simple & therefore timeless. Our furniture is made to last & we hope that we are building a brand that people want to hold on to & that can be handed down to future generations.

- Supporting local businesses that use eco-friendly materials is important to us. (Eg: using wool for our chair pads & sustainably grown oak for our furniture).

- We are focusing on reducing paper and recycling all materials possible. This includes removing packing lists & covering letters from orders & emailing them instead. We are working on new ways to pack without causing damage to the products when they are freighted.

- Our supply chain has been audited, to see what practices can be improved on.

- We think about what we gift at Christmas, eg: edible treats in recyclable packaging and Kowhai trees for planting.

Re-thinking Mobility

Ico Traders operates from our home office & all staff live close by, minimising the carbon footprint of each daily commute & lowering traffic congestion.

Skype and WeChat is used to communicate with overseas suppliers (this was in practice even before the Covid Pandemic, with international travel kept at a minimum)

We use suppliers & manufacturers that are situated in close proximity of each other & have set specific days to visit, making less trips, less travel. We ask for materials from our suppliers to be sent direct to our manufacturers, to reduce courier impacts.

Direct shipping to customers is offered to our wholesalers, to reduce courier impact.

Our plan is to invest in an electric van when Bernie the Berlingo is replaced.

Eco Standards We Hold and Support

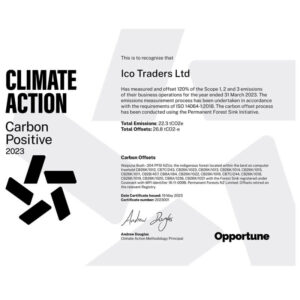

- Carbon Positive Certified (Ico Traders) Read more about this standard

- Carbon Click (Ico Traders) Read more about this standard

- Standard 100 by Oeko-Tex (Wilson + Dorset and James Dunlop) Read more about this standard

- Forest Stewardship Council (FSC) Read more about this standard

- Programme for the Endorsement of Forest Certification (PEFC) Read more about this standard

- CertiSource (Herman Pacific) Read more about this standard

Climate Positive Business Operations

As an organisation we are extremely conscious of our carbon footprint. Since early 2021 we have been auditing our carbon emissions & offsetting them by 120%, (as well as making changes to reducing them). We are proud to be audited & certified for the 2023 financial year, as a Climate Positive Business by Opportune. We choose to invest in credits sourced from Permanent Forests Ltd, as everyone working at Ico Traders has ties to Banks Peninsula. Our funds help to grow and protect the Waipuna Bush in Banks Peninsula, New Zealand, delivering climate resilience, protecting waterways, controlling erosion, conserving biodiversity and developing community economy.

2023 GHG Emissions Inventory Report – ICO Traders

By understanding the emissions profile of our business operations, we can start to strategically reduce them.

Opportune is committed to helping us reduce carbon emissions to avoid dangerous climate change.

- Measure and verify our carbon footprint.

- Use this footprint measurement to develop and implement a carbon reduction plan.

- Offset carbon emissions that could not be reduced by at least 120%.

- Certify the result.

MEASURE – REDUCE WHAT YOU CAN – OFFSET WHAT YOU CAN’T

Health and Safety

It’s important to us to provide a health and safety conscious workplace for our staff. Our business is audited for health and safety by Safe and Sound Solutions, New Zealand.

Our Goals

- Redesigning packaging to get rid of all polystyrene. (Achieved 2022).

- Replace ALL plastic packaging with recyclable materials. (This has already been achieved, for all future orders 2023).

- Create a rehoming page for once loved pieces. (Achieved 2023, see out RELOVED section).

- Reduce packaging where possible – even recyclable packaging. (Reviewed several times a year).

- Keeping carbon positive rather than carbon neutral.

- Full transparency of our supply chain reported and posted on our website

- Working closely with local and environmentally aware businesses.

This is a never-ending project to be assessed and improved on every year for the foreseeable future.

START SMALL, THINK BIG, MAKE CHANGES

Companies We Work Closely With

Our Suppliers

Our Powder Coating

We work very closely with the team at Industrial Painters for all our powder coating needs. They are located in Sydenham, only a 12-minute drive from the home office! They are a one-minute drive from the metal workers we use and just around the corner from our cushion makers, (you could run there in 2 minutes!).

All Ico Traders’ furniture that is available for custom colour is supplied prepped, ready to be coloured. This eliminates the degreasing, stripping and blasting process other products would have to go through. Industrial’s process of powder coating uses an environmentally safe waterfall of recyclable water to catch powder particles before they can be released into the air. All ovens are run on electricity.

We use exclusive Ico Traders powder that we import from China and Dulux PBG powders, which are made here in NZ. Dulux has become the largest manufacturer of water-based paints in NZ and Australia; they are market leaders in introducing VOC paints (Volatile Organic Compounds).

Our Oak Furniture

Neil our craftsman of all things oak has a workshop located in New Brighton, a 20-minute drive from our office.

The Oak used by Ico Traders is sustainably grown by mills on the east coast of America. It is sourced through a New Zealand owned supplier & shipped here via sea freight. Mirotone supplies the nontoxic finishes and stains that Neil uses, their factory in Wellington produces 95% their products. All metal components are manufactured offshore & imported by a New Zealand owned company called Mainland Fasteners.

Our oak furniture is shipped to our customers nationwide via road freight. If the customer is local, Neil will personally deliver it in his company van, or we will pick it up ourselves.

Employees at Parsons Green are reducing emissions by biking and carpooling to work.

The oak we use is associated with many mills across America through the American Hardwood Organisation. The AHO are dedicated to sustainable forest management and conduct their business in accordance with strict environmental practices. They purchase their timber under the Forest Stewardship Council (FSC), the Programme for the Endorsement of Forest Certification (PEFC) and CertiSource.

The AHO places a large importance on making sure harvest levels do not exceed what the forest grows so that future growth capability is not degraded. In fact, the U.S Forest Service’s most recent study indicated that the hardwood forests are growing more wood each year than is lost to fire, insects, disease and harvesting.

Herman Pacific is committed to finding new ways to lessen waste. So far they have been able to reduce to almost zero waste by using off-cuts to produce the heat used in kiln-drying timbers, as well as in the production of their proprietary Vertibat product. They also supply local capsicum growers and equestrian facilities in Northland with sawdust from non-treated timbers.

Read more: About Oak

Our Chair Pads

James Dunlop Textiles supply us with wool textiles, used for all chair pads accessories at Ico Traders. New Zealand wool is sent to Italian mills t0 produce the fabrics. They are part of a larger distributed group of textile manufacturing that uses many certifications :

- ISO 500001 energy certification

- GOTs

- OCS

- GRS

- Standard 100 by Oeko-Tex

James Dunlop focuses on their current environmental and social impact by making incremental improvements to their products and processes to lessen any negative impact, while simultaneously delivery high quality products. James Dunlop has analysed their business model to see where improvements in emissions can be made. Since making changes to their freighting methods and focusing on mill to warehouse freight, they have seen a tangible shift in their business model and the amount of emissions it takes to deliver their product to the market. James Dunlop is dedicated to looking for alternatives to plastics used in the shipping of fabrics.

James Dunlop deliver their fabric straight to our manufacturers in Christchurch who make the cushions. This is more efficient and cuts out unnecessary freight emissions.

The Velcro, zips and thread used for the cushions are supplied by New Zealand companies who import the products from offshore. We feel this is an area we can improve on, to see if we can find products that are locally made.

The foam inners for our chair pads are made onsite in a factory here in Christchurch. The environmental impact of making this foam is minimal & there are no combustible gases produced.

The foam offcuts are recycled and used in flooring underlay.

Our Website

For all our digital needs, we work closely with The New Black Online Solutions in Christchurch. In terms of sustainability, their footprint is very low! They utilise their technological knowledge and keep the vast majority of their work online to avoid printing and use online meetings where possible.

The staff also mostly work from home during the week. Kylie is conscious of her environmental impact and purchases carbon credits to offset her emissions when flying and drives an electric vehicle.

When they do client gifts, they make sure to use local suppliers and edible gifts with recyclable packaging so there is no plastic waste.

Our Office Stationary

We buy our home office supplies from 2 New Zealand companies:

Better Packaging Company is a carbon neutral BCorp helping us to be better. They supply us with compositible courier labels & satchels & recycled ‘POLLAST!C ‘ courier bags. Their goal is to run a ‘zero waste’ enterprise through re-use/re-purposing, recycling and composting.

Read more about The Better Packaging Company & their environmental certifications

Total Packaging is a New Zealand company in Christchurch that supplies us with stationery for the home office. They import the bulk of their products however; some are manufactured locally. Total Packaging source both directly from factories where they are made, as well as importers. They carry out audits of their major suppliers to ensure only ethical and legal business practices occur.

* We feel this is an area we can improve on by looking for and using more eco product options.

Our Brands

Wilson & Dorset

The sheepskins used by Wilson & Dorset are a byproduct of pastoral farming in New Zealand. As the sheep are raised primarily for meat, utilising their wool is important for making full use of the resource. Wool is durable, long-lasting and 100% biodegradable. In terms of animal protection, New Zealand is placed first in the world thanks to the enforcement of comprehensive animal welfare regulations.

Wilson & Dorset’s supplier have a full time purchasing manager who travels from the top of the North Island to the bottom of the South Island to source premium quality sheepskin. Once sourced, the sheepskin is sent to an offshore production facility in Northern China where a third party regularly monitors all stages of the production process. Their supplier is very conscious of their environmental impact and has made great improvements in terms of water, energy, emissions, recycling, and chemical reductions with the help of the Oeko-Tex standard. For instance, they have adopted solar energy to heat up to 2,000,000 litres of water per week. They have also decommissioned their coal boiler for natural gas and have since seen a significant reduction in carbon emissions.

Read more: About Wilson & Dorset

TIPTOE

TIPTOE is an innovative French furniture company. They have created 5 principles for sustainable design that guide their design process

- Make things simple

- Make more with less

- Use the right materials

- Build to last

- Design for disassemble

Their furniture and products are designed in Paris and made in factories throughout Europe in France, Belgium, Bulgaria, Poland, the Netherlands, Lithuania, Croatia, Romania and the United Kingdom. Their main partner is a family run factory based near the Alps Mountain in Chamonix.

TIPTOE has chosen to use robust materials for their furniture, that has either been recycled or can easily be recycled. This includes steel, aluminium, wood and recycled plastic. Currently, 80-90% of all steel used in Europe is estimated to have been recycled at least once. Recycling steel also produces significant energy savings of around 75%.

Their wood is exclusively sourced from European forests that are sustainably managed and operate under the FSC and PEFC labels.

TIPTOE is also constantly working on ways to further use up-cycled materials like recycled plastic in their products. (The Genova and Venezia Recycled Plastic Coffee Table, the Recycled Plastic Chair & the Lou Stool)

Compac Stone

The Sandstone and Riverstone Willowby Cube tops are made right here in Christchurch, by The Granite Bench Company.

The terrazzo style, stone tops are made from a renewable source of vegetable origin ran BIOresin from Compac.

The non-silicon surfaces have an NSF certification for food standards, meaning there are safe and hygienic for use in direct contact with food.

Compac’s ultimate aim is to be an eco-efficient company that uses 100% recycled or renewably sourced raw materials for the manufacture of their products.

Pressed Tin Panels

Pressed Tin Panels is an Australian, family owned and run business that is located in Bathurst, Central West NSW. They use high grade metals such as aluminium, galvanised, copper and zinc. Once the panels arrive into New Zealand, they are shipped nationwide, directly from our distribution centre in the North Island.